Types of Steel used in the production of welded structures

According to the opinion of world experts, we can distinguish about 3500 steel grades that differ from each other in chemical and physical properties as well as in environmental properties.

What is steel, and what is the classification of its grades? What is its use? The answers to these questions are included later in the article.

What is Steel?

Steel should be defined as an iron-carbon alloy, wrought and heat-treated, with a carbon content of not more than 2.11%, which correlates with the limited solubility of carbon in iron. It should be kept in mind that in the case of alloy steels, the carbon content can be much higher.

Steel Division

Taking into account the chemical composition, steel is divided into:

- alloy steel:

-low-alloy, –

medium alloy, –

high-alloyed,

- unalloyed (carbon) steel:

low carbon,

medium carbon, and

high carbon.

Depending on the application, steel is divided into:

- structural steel,

- tool steel,

- special steel.

Characteristics of individual types of steel

- NON-ALLOY (CARBON) STEEL

Carbon steel contains trace amounts of alloying elements. This type accounts for about 90% of the total steel production. As presented above, depending on the carbon content, unalloyed steel is divided into low-carbon steel with a carbon content of up to approx. 0.3%, medium-carbon steel with a carbon content of 0.3 to 0.6%, and high-carbon steel with a carbon content of above 0.6%. Carbon steel is commonly used in the production of mechanical equipment parts and steel structures.

- ALLOY STEEL

It is a type of steel in which, apart from carbon, there are other alloying elements, such as silicon, manganese, nickel, copper, titanium, aluminium, or chromium, with content of several to several dozen per cent. The presence of additional elements in the composition, depending on the degree of their content, affects the physical properties of steel, i.e. its corrosion resistance, strength, hardenability, weldability, ductility, or deformability. Alloy steel can be divided successively into low-alloy steel, in which, apart from carbon, there are traces of other alloying elements; medium-alloy steel, containing from 5 to 10% of alloying additives other than carbon; and high-alloy steel, where the content of alloying additives is over 10%.

Alloy steel is currently used in the production of, among other things, automotive parts, power generators, electric motors, pipelines, and transformers.

- STRUCTURAL STEEL

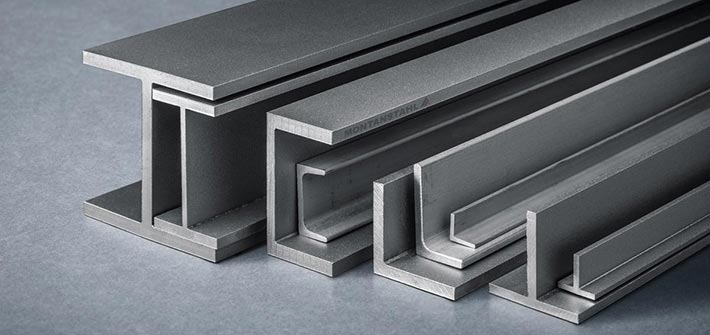

As the name suggests, it is intended for the construction of steel structures, machine parts, and equipment of standard use. It is delivered in the form of ready-made steel products. In a situation where elements of the structure or parts are exposed to work in difficult conditions, the structural steel is replaced with special steel. This type of steel is divided, among others, into general-purpose structural steel, higher-quality structural steel, and low-alloy structural steel.

- TOOL STEEL

It is a type of steel intended for the manufacture of tools as well as the processing of materials. Tool steel contains cobalt, molybdenum, vanadium, and tungsten in its composition, thanks to which it is characterised by great strength, high abrasion resistance, and deformation.

- SPECIAL STEEL

It contains a large amount of alloying additives and additionally requires complex thermal treatment, which in turn is associated with high production costs, so its use in industry is not as common as, for example, structural steel.

The use of Steel

Currently, steel finds its application in many different fields of technology. Of course, it is most often used in construction to create solid and durable steel structures. Nevertheless, it should be remembered that steel is used in many industries in the production of, among others,

- electrical installation,

- car bodies,

- network, rail, and traction infrastructure,

- steel products, including wires, spikes, cables, sheets, rods, steel profiles and tapes,

- ready-to-use elements, including furniture, steel structures, including small architecture.

- machine parts, facade, and roofing.