Designing any product, even the simplest, is a complex process. It involves finding the best solution to a given problem in the most aesthetically pleasing form and meeting customer requirements. In short, the process is as follows: initially, you need to create a concept for a given product; then, preliminary sketches are prepared, the market is researched, an appropriate niche is searched, the demand for a given product is monitored, production and sales costs are estimated, and conclusions are drawn as to whether a given product has a chance of being accepted on the market. Then, a project is created, and technical documentation is created based on how the prototype is constructed. If the prototype meets all the requirements, then the project is approved and transferred to serial production. If not, then appropriate corrections are made and another prototype is created. Generally, the same procedure is repeated in all industries, with minor differences. What does it look like in the case of steel structures? Are there significant discrepancies in how steel structures stand out from the competition?

The Design of Steel Structures

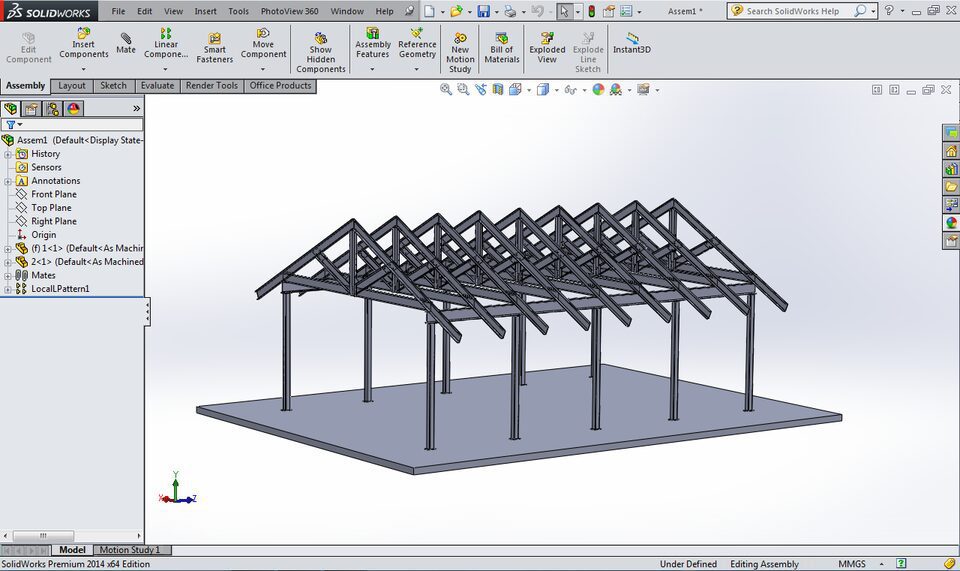

The process of designing steel structures does not differ much from designing items made of other materials, but as you know, each industry has its specificities. The design of steel structures is the so-called synthetic approach to extensive and complex provisions of standards, and an additional indication of their practical application is already evident during the first stage of dimensioning and creating basic designs of steel structures, such as compression or tension bars, pipes, profiles, columns, beams, nodes, etc. This also applies to more complex structural systems, such as transverse systems or frames.

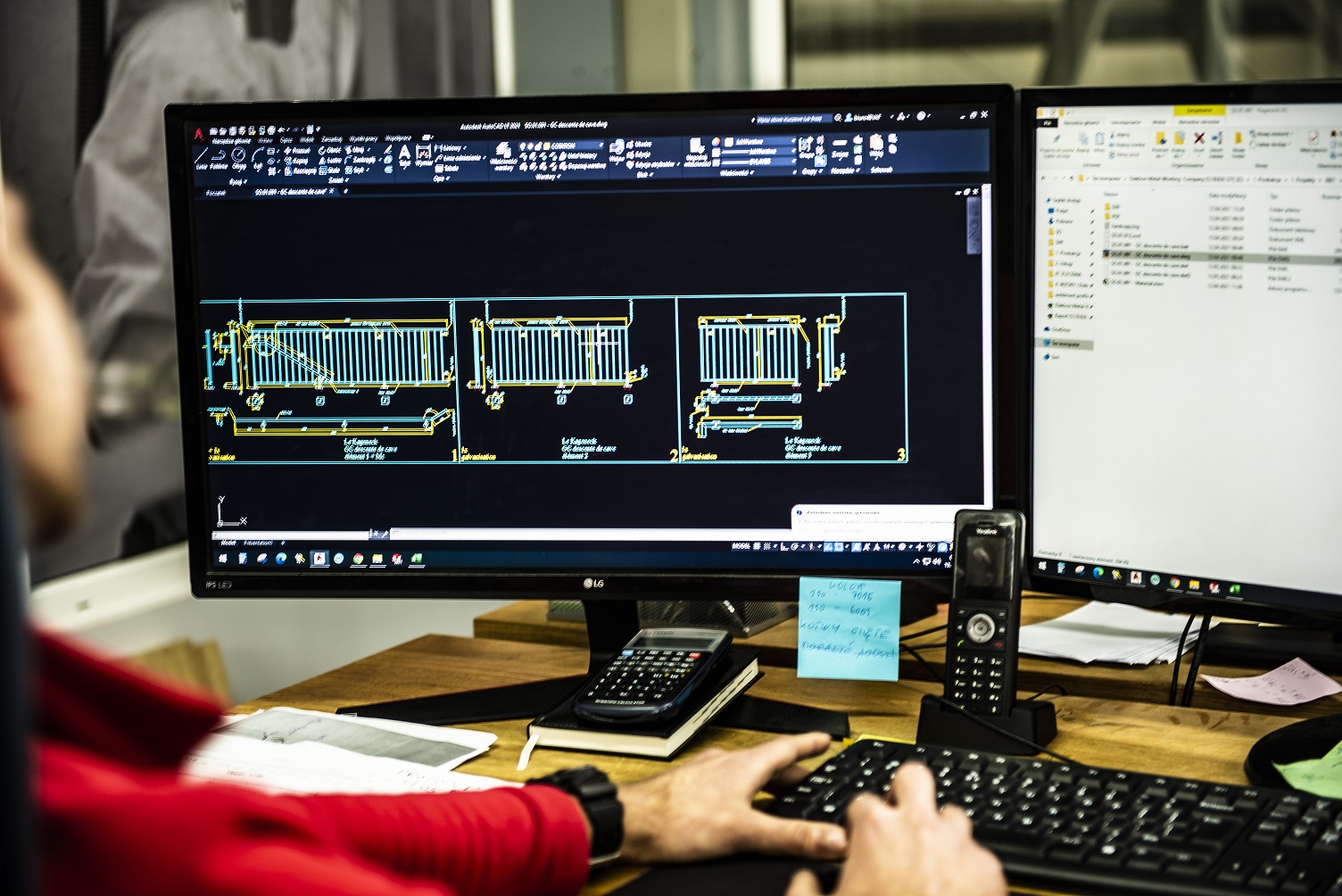

Designs for steel structures

Designing steel structures involves accurately sizing the structure and checking connections to meet standards. It also includes checking for bending, buckling, and other limit states.

Prototyping of steel structures

Prototyping is used to check product parameters and quality, optimize the user experience, and evaluate the performance of design options for creating the final solution. There are several types of prototyping:

- functional prototype—designed for functional tests.

- A PoP (proof of principle) or PoC (proof of concept) is a prototype based on the quality of its construction, design, and use of technology, not on its appearance.

- Usability prototype: determining the usability and ergonomics of the solution

- Visual prototype: optimizing and focusing on the visual aspects of the product.