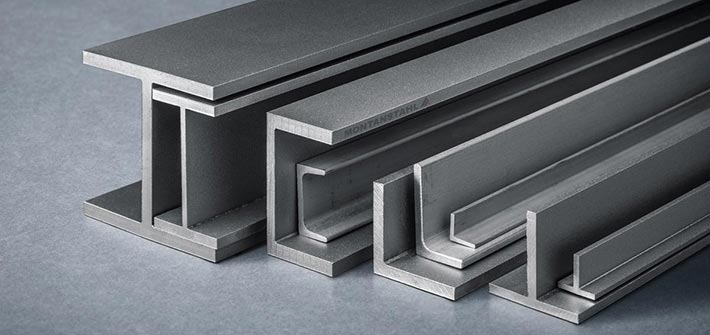

Metalworking is crucial in many industries, including automotive, construction, furniture, mining, metallurgical, and shipbuilding. It is essential for building houses, installing plumbing, building bridges, manufacturing cars, and other complex activities.

It is also necessary for the design of small-sized elements, such as those used in the decoration or furniture industries. However, not everyone knows what metal processing is, what its types are, and how to create steel products. Therefore, we will take up these issues in today’s article.

What is metal processing?

Metalworking involves using various techniques to change the shape of metal parts. The purpose of metal processing is to change its dimensions and physical and chemical properties. Metal processing is a set of technological activities carried out in industrial plants around the world. It is especially important in factories and production plants.

What are the methods of metalworking?

The breakdown of metalworking methods is as follows:

- machining—a process consisting of giving the elements the expected shapes and dimensions by fragmentary removal of parts of their surfaces. This makes it possible to change the structure of the surface of the object, i.e., to bring it to the shape desired by the recipient. Metal cutting consists of three processes: turning, milling, and grinding.

- plastic working— action during which the material is shaped, both dividing it and changing its properties or structure. This is due to the plastic action. Processing can be done cold, that is, at temperatures lower than the recrystallization temperature, or hot when this temperature is higher.

There are four types of plastic work:

- Forging—manual or mechanical—is about giving the desired shape through force, pressure, and crushing.

- Embossing is most often used for sheets, strips, plates, and foil. The shape is achieved during the process of separating the secondary material from the base material. It consists of cutting or other forms of plastic shaping of the material.

- Drawing involves stretching and reducing the diameter of material in a controlled manner.

- Bending—that is, changing the shape of a given material while maintaining the same transverse dimensions — Often, metal bending is preceded by a hydrothermal treatment that increases the deformation tendency.

- Heat treatment is the process of changing the properties of alloys by exposing them to temperature changes. This treatment is commonly used for steel due to its tendency to respond well to this process. The scope of treatment, in this case, includes hardening, annealing, solution treatment, and stabilization.

- Chemical treatment of metals is the process of applying a protective coating to the metal surface to increase its strength and prevent corrosion.

- Thermo-chemical treatment is a method mostly used for iron-carbon alloys like steel, cast steel, and cast iron that modifies their physical and chemical properties through heat and chemical influence.