Currently, on the Internet, we can find hundreds of offers from metallurgical and machine companies, offering their services for the plastic processing of metal materials. Enterprises compete by enriching their assortment with the latest machines, improving the qualifications of their employees, and finding the most innovative and practical processing methods. But what about an entrepreneur who is not closely related to the industry and lacks the knowledge needed to identify the best method of bending pipes and profiles? How to choose the most appropriate way out of so many possibilities?

First, he can fill in the knowledge gaps by, for example, reading this article. Today we will see the difference between bending pipes on mandrel benders and bending pipes on three-roller benders, and we will briefly present the advantages of both options.

Bending pipes and profiles on a three-roller or mandrel bender?

Bending machines are one of the types of devices used for the so-called plastic processing of metals. The main task of bending machines is usually the bending of pipes and metal profiles that need to be reshaped. Are the two types of machines different? Let’s start with a three-roller bender.

What distinguishes a three-roller bender?

It is a much less advanced machine than a mandrel bender. This type of device is used in the automotive industry, during the construction of machines and steel structures, or in the production of railings. The cost of such a machine ranges from several thousand to even tens of thousands of zlotys.

The bending of pipes and profiles on a three-roller bender takes place by passing the material through three dies. The upper roller presses the material, which bends the pipe or profile. Bending with this method allows for the obtaining of arcs or spirals. The three-wheel bender offers slightly fewer possibilities when it comes to the process of bending pipes and profiles because, for example, compared to a mandrel tool, it does not allow for bending elements at an angle. They are also not very suitable for applications where thin-walled pipes and profiles need to be bent, or where small bending radii are desired, which is why mandrel benders are mainly used for this type of work.

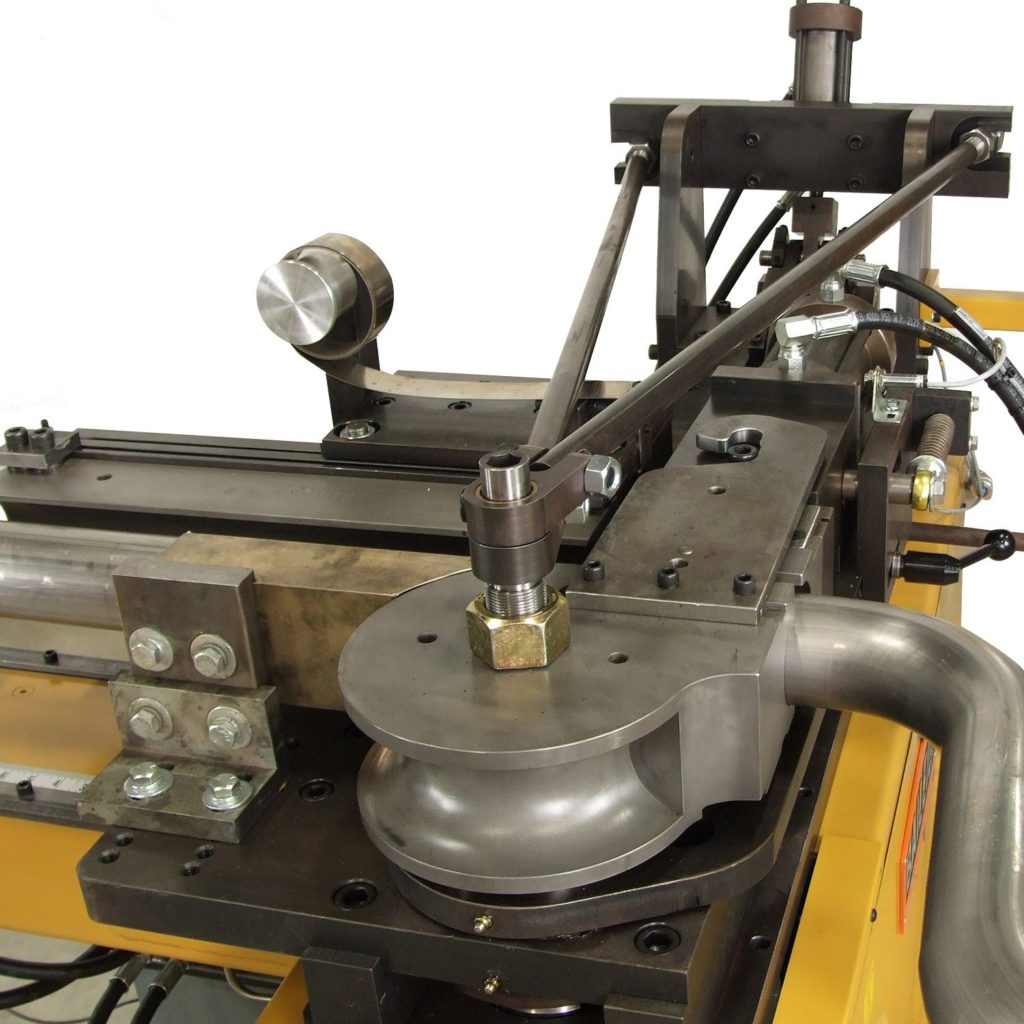

What distinguishes a mandrel bender?

There are two basic types of mandrel benders. The first is a so-called “mandrel bender,” which is driven hydraulically or electrically. However, it is slowly becoming a thing of the past due to the availability of a numerically controlled (NC) mandrel bender. It is an advanced numerically controlled machine, which causes the machine to feed the tube by itself and then rotate it. The cost of such a machine is much higher than that of a three-roller bender and usually amounts to several hundred thousand zlotys, but the full automation of bending pipes and profiles guarantees fast implementation time, high repeatability, and a low margin of error, which is why this type of machine is currently the most popular.

The mandrel bender bends the material by inserting the mandrel into a pipe or profile and then bending the element to the required angle. Depending on the type of die, we can obtain a different bending radius. The use of a mandrel bender allows you to bend pipes and profiles at the right angle.