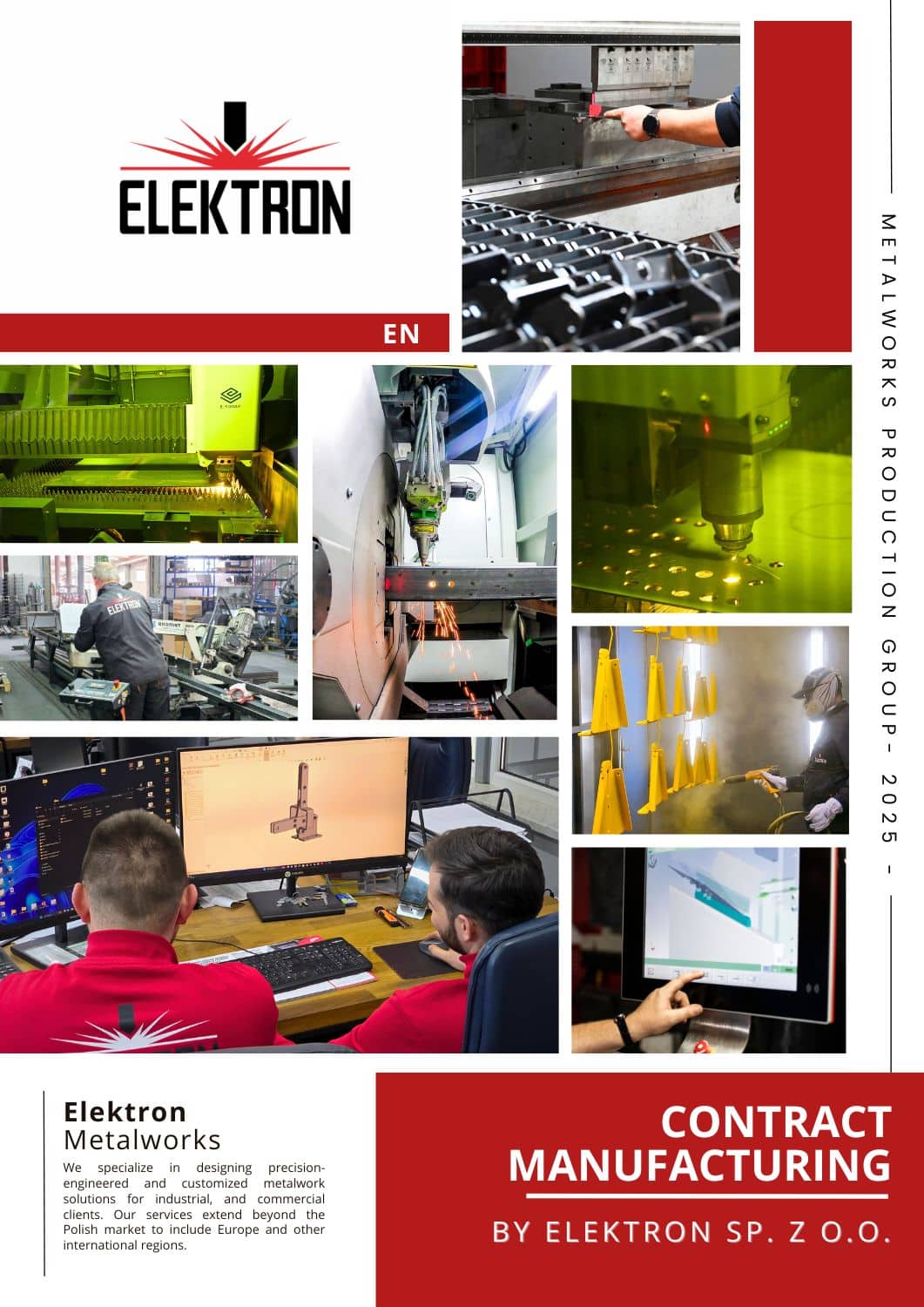

“Elektron Sp. z o.o. is a modern company that has been dynamically growing in the metal processing industry since 2018. Based in Poland, we specialize in advanced metal fabrication, offering precision and quality to global clients.”

We employ over 100 highly qualified specialists in our steel processing department. Their expertise and commitment enable us to provide top-quality metal fabrication services that meet the highest industry standards.

Our metal processing facility covers over 3,500 m² and is equipped with cutting-edge machinery and modern equipment. This allows us to deliver precise, efficient, and high-quality metal fabrication services for every project.

On average, we implement 54 projects per month.

(based on data from 2021)

Elektron is a leading metal fabrication company in Poland, offering precision laser cutting, sheet metal bending, pipe and profile bending, professional welding (MIG, MAG, TIG), and durable powder coating services. As a modern and fast-growing organization, we combine advanced technology with professional expertise to deliver high-quality metal components and custom steel solutions.

Our skilled team and growing experience allow us to meet even the most demanding customer requirements. With a wide range of products and services, we ensure precision, reliability, and excellent customer support for clients across various industries.

At Elektron, we are a leading manufacturer of metal components in Poland, specializing in custom metal fabrication, steel structures, metal furniture, and store equipment. With years of experience and advanced manufacturing technologies, we provide high-quality, tailored solutions to meet the needs of our international clients.

As a manufacturer of metal components in Poland, we offer precision fabrication services for various industries, ensuring durable and reliable metal parts that meet the highest standards. Whether it’s for automotive, construction, or custom projects, our state-of-the-art equipment and skilled team guarantee excellent results.

Elektron is also a trusted manufacturer of steel structures in Poland. We specialize in custom-designed steel structures for industrial, commercial, and residential applications. From industrial warehouses to bespoke building frameworks, we create robust, durable steel structures with exceptional craftsmanship and precision.

If you’re looking for stylish and durable metal furniture in Poland, Elektron provides a wide range of custom solutions. From metal desks and metal chairs to metal storage units, we design and manufacture high-quality furniture for both residential and commercial spaces. Our metal furniture is not only functional but also designed to enhance the aesthetics of any space.

As a leading manufacturer of store equipment in Poland, we offer a comprehensive range of products for retail spaces. Our custom solutions include metal display stands, shelves, cash counters, and bicycle racks designed to improve store functionality and customer experience. With Elektron, you can find tailored store equipment solutions that align perfectly with your business needs.

If you’re looking for a reliable manufacturer of metal components, steel structures, metal furniture, or store equipment in Poland, Elektron is your trusted partner. Contact us today to discuss your project needs and get a customized solution designed to fit your requirements.

Our facilities are continually being expanded, and we are accumulating experience. We are willing to work with you on any project. Because of our previous expertise and facilities, we are able to maintain high quality standards and thereby satisfy a large number of clients.

Comprehensive implementation of all projects is guaranteed by our specialised team consisting of:

When implementing projects, we use software that speeds up and guarantees comprehensive project service.

We work on software such as:

Modern technology guarantees repeatability and precision in realization of even the most complex elements

Thanks to the extensive practice in our offer you can find:

Laser Cutting is a thermal processing method that concentrates the energy of a powerful laser beam on very small areas (ranging from 0.1 to 0.5 mm). It is an exceptionally fast, reliable, and flexible material processing method, significantly reducing production cycles.

Laser cutting is primarily used for thin sheets, enabling the rapid production of both simple and complex shapes from various materials up to 20 mm thick, while maintaining a very high level of precision. Additionally, due to the highly focused beam, laser cutting of sheets does not cause deformation or material loss, offering excellent efficiency.

Furthermore, we provide laser cutting services for pipes and profiles. Our facilities are equipped with two laser cutting machines designed for cutting profiles, including pipes, sections, angles, channels, T-sections, and special profiles.

In our offer, we also provide profile processing services such as tube and profile bending using a spindle bending machine. Bending tubes and profiles with CNC machines ensures repeatability and the ability to produce large quantities of parts in a short time. Thanks to the advanced CNC-controlled tube and profile bending machine, the process is optimized to such an extent that we can offer parts at highly competitive prices. The bending machine is suitable for bending large batches, making us capable of handling any order, no matter the size.

Using modern machines, we optimize the threading process, which allows us to significantly reduce production costs while maintaining the highest precision.

For threading, we use advanced pneumatic threaders that help optimize production costs by speeding up the hole threading process.

Welding of steel and stainless steel components using MIG/MAG and TIG methods, as well as spot welding.

Before the production process is completed, each product requires surface preparation. We have extensive experience in steel grinding. All components undergo rigorous quality control to ensure the final result meets even the highest expectations of our customers.

To protect the product from corrosion and achieve the desired appearance, an appropriate coating is applied to the product.

Quality is our top priority.

With the implementation of management systems, we offer products of the highest quality. Our team of quality controllers oversees the production process and ensures precise execution.

During the assembly stage, our experienced team of assemblers and electricians not only connects metal components but also enhances the structure with other non-metallic elements.

We combine metal with materials such as PVC, wood, and glass, and also carry out electrical installations.

Packaging is customized individually to the type of product and its dimensions.

We will deliver the products to the address you specify, regardless of the location.

Comprehensive project execution is guaranteed by our specialized team

When executing projects, we use software that accelerates work and ensures comprehensive project support.

We work with software such as:

Sheet Metal Bending – Modern Precision for Demanding Projects

Using advanced press brakes from renowned manufacturers, we perform sheet metal bending with the highest level of precision and repeatability. Our machinery includes three press brakes capable of processing sheets up to 3000 mm in length.

The use of cutting-edge equipment enables us to handle complex projects with attention to every detail. The bending process is digitally controlled, ensuring exact project reproduction and production time savings.

Our sheet metal bending services are the perfect solution for companies requiring elements with custom shapes and precise dimensions. We fulfill orders according to client specifications, guaranteeing accurate execution and exceptional quality of finished components.

Laser cutting is an advanced thermal processing method that focuses the energy of a powerful laser beam on very small surfaces, starting from just 0.1 mm. This technology is fast, precise, and highly flexible, allowing for significantly reduced production cycles and minimal material loss.

Sheet metal laser cutting is primarily used for flat materials and profiles to quickly and effectively produce both simple and complex shapes from sheets of varying thickness – up to 40 mm. Thanks to the focused laser beam, the process offers exceptional precision, eliminates material deformation, and prevents waste.

We also offer laser cutting of tubes and profiles. Our modern technological facilities include high-quality laser cutting machines designed specifically for precise profile cutting, including tubes and profiles made of steel, aluminum, and stainless steel. With advanced technology, we ensure repeatability, accuracy, and efficiency for every project.

Tube and Profile Bending – Precision and Repeatability with CNC Technology

We offer tube and profile bending using modern CNC mandrel bending machines. Thanks to numerical control technology, we ensure high repeatability, precision, and the ability to deliver large batches quickly.

Our CNC bending machines allow for:

Tube and profile bending is widely used in construction, furniture, and automotive industries. With advanced technology and an experienced team, we deliver projects with the highest quality and on time.

Metal Threading – Precision and Production Cost Optimization

With modern machines, we optimize the metal threading process, which significantly reduces production costs while maintaining the highest level of precision.

We use advanced pneumatic tapping machines that accelerate the threading of holes, improving production efficiency and reducing lead times. This technology allows us to offer competitive prices while meeting the highest quality standards.

Welding of Steel and Stainless Steel – Precision and Advanced Technology

We offer professional welding of steel and stainless steel components using MIG/MAG and TIG methods, as well as spot welding. With our modern technological facilities, we ensure high precision, repeatability, and efficiency in project execution.

Our equipment includes:

Thanks to advanced technology and the experience of our specialists, we deliver solutions for the construction, automotive, furniture industries, and more. Each project is completed to the highest quality standards and within optimal timeframes.

Surface preparation is a key stage before completing the production process. With our extensive experience in steel grinding, we ensure the highest quality surface treatment by removing any imperfections.

Each component undergoes precise grinding, which guarantees smoothness, an aesthetic appearance, and proper preparation for further processes such as painting or welding.

All products pass through a rigorous quality control process, ensuring the final result meets the expectations of even the most demanding clients. Our attention to detail and the use of modern technologies ensure repeatability and an excellent finish in every project.

To protect products from corrosion and give them the desired final appearance, we use advanced technologies for applying protective coatings.

We offer:

Each process is tailored to the specific needs of the project to deliver maximum durability, aesthetics, and functionality of the finished component.

During the assembly stage, our experienced team of assemblers and electricians not only connects metal components but also enhances the structure with other non-metallic elements.

We combine metal with materials such as PVC, wood, and glass, and also carry out electrical installations.

Packaging is customized individually to the type of product and its dimensions.

Quality is Our Top Priority

Quality is our top priority at every stage of production. Thanks to our implemented quality management systems, we offer products that meet the highest standards.

Our experienced quality control team monitors the production process and ensures the precise execution of each component. Thorough supervision guarantees that the final product meets the expectations of even the most demanding customers.

We provide efficient and timely delivery of products to the address you specify, regardless of location. Our logistics solutions ensure that the ordered components arrive safely and on time, both domestically and internationally.

By working with trusted carriers and leveraging our experience in serving business clients, we handle single deliveries as well as large orders. Our team oversees every stage of the process – from careful packaging to seamless logistics.

Do you have any questions about us? Please don’t hesitate to get in touch with us!

Watch a short video to see how precision, advanced technology, and extensive experience converge in our production process

In order to maintain the highest standards, we are periodically audited by accredited certification bodies, which is confirmed by issued certificates in the scope of ISO 9001, ISO 1090 EXC3, ISO 3834.

Elektron spółka z ograniczoną odpowiedzialnością

Sulistrowa 33

38-462 Sulistrowa,

NIP: 6842640074

REGON: 360939126

KRS: 0001022315

Customer service hours: klienta

Monday – Friday, 7:00 a.m. – 4:00 p.m.

CUSTOMER SERVICE OFFICE:

+48 13 307 03 03

OFFICE: