Precision Pipe and Profile Bending Services for Steel Components

Bending pipes, we usually use the cold bending method, but in the case of such a need and the possibilities of a given material, we also work at a specific temperature. For this type of order, we use a professional three-roller tube and profile bender. It provides a maximum bending angle of 180 degrees and a diameter of 54 x 3 mm.

We also offer specialized, very precise CNC tube bending. We process pipes made of various materials, including aluminium, stainless steel, and copper. This process involves the plastic processing of materials in such a way as to change the curvature of the pipe to the desired shape. It is done by squeezing some fibres and stretching others. Importantly, it does not affect the appearance of the material and does not change its technical properties.

Thanks to a high-class bending machine, we can produce any number of identical parts, including those with complex shapes. We carry out wholesale orders. The elements manufactured by our company are distinguished by excellent quality and accuracy of bending. We can efficiently execute any order in the field of bending profiles in an extremely precise way, without the occurrence of undulations on the walls or distortions of asymmetrical profiles, e.g. flat-convex or concave-convex.

After providing the services of bending sheet metal, at the customer’s request, we can further process the material, e.g., by removing any defects or inaccuracies in the product. In addition, we also offer additional services such as powder coating that effectively protects metal parts, abrasive machining, or threading holes.

Customized Metal Bending Solutions for Various Industries

We offer professional, comprehensive bending pipes and bending profiles on CNC mandrel bender. We are a company with a team of qualified and experienced specialists. We approach each order individually, guaranteeing careful and reliable work. Handing over this type of service to experienced people is the best solution because although pipe bending seems to be a rather simple process, in fact, especially with complex shapes or non-standard materials, bending can be a challenge. We regularly improve our competence by participating in training or courses. Thanks to this, we can offer the highest quality and most modern services. We ensure the timely execution of orders. We also carry out work based on our projects or those prepared by the client.

For our service of CNC mandrel bending is directed at clients from various fields and industries. We guarantee favourable and competitive prices. We provide free, non-binding, individual work quotes. We also provide professional technical advice from specialists throughout the implementation of projects and orders. Thanks to this, there is a greater chance of finding a device that will perfectly match the specificity of the work performed. We have the best equipment that will allow us to carry out even the most demanding projects and meet the expectations of every customer, even the most demanding.

Processing parameters for tubes:

20 x 1.5 mm

black steel and stainless steel

(The potential for rolling)

21.3 x 2 mm

black steel and stainless steel

(The potential for rolling)

33.7 x 2 mm

black steel and stainless steel

(The potential for rolling)

42.4 x 2 mm

black steel and stainless steel

(The potential for rolling)

42.4 x 3.2 mm

black steel and stainless steel

(The potential for rolling)

48.3 x 2 mm

black steel and stainless steel

60.3 x 2 mm

black steel

Processing parameters for square profiles:

40 x 40 x 2 mm

black steel

30 x 30 x 1.5 mm

black steel

(The potential for rolling)

40 x 20 x 1.5 mm

black steel

(The potential for rolling)

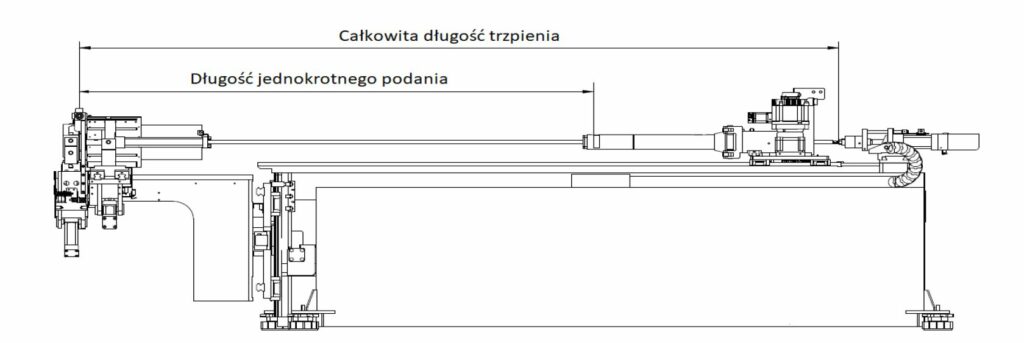

Technical Specifications:

65 x 2.2 mm

3

2xD

540x120x155 cm

up to 190 °

Up to 220 mm

Advanced CNC Pipe and Profile Bending Technology

There are many mandrel bending machines on the market. We can find simple and manual devices, usually used in small workshops, as well as automated and specialised ones, used by inexperienced companies and plants and operated by specialists. Such devices allow you to perform several processes simultaneously.

Mandrel bending is used in many industries: in construction, automotive, aviation, and even in the furniture industry. CNC bending machines are most often intended for mass production of simple elements as well as those requiring precision and detailing.

Bending on mandrel benders

The most popular CNC benders are mandrel bending. They are characterised by a special tube feeder that enables automatic bending. All movements are carried out thanks to precise mechanisms and microcomputers, which allow for very high accuracy and repeatability of manufactured elements. The use of this type of device also shortens the bending time compared to traditional, manual machines, which is a very important factor affecting savings in the production process that requires pipe bending.

The CNC mandrel benders machine can have a function that allows them to bend pipes and profiles on the so-called “the matrix,” which additionally allows them to wind the pipes on rolls. This is a function called “push-bending.” The pipe is pushed by the feeder between special rollers that position it so that it is bent in the right place. This method also allows for three-dimensional shapes by rotating the pipe. In this way, you can make a spiral, among other things. Benders with this type of function are used primarily in the production of complex elements.

By controlling the machines with a CNC controller, the machine can speed up the bending process. Mandrel benders work automatically, so they are primarily used in the serial production of complex elements. Thanks to the use of the latest technologies, the most complex elements can be made in a short time and with precision. Using the latest technologies, it is possible to obtain virtually unlimited shapes when bending. The limitations that we may encounter may result mainly from the material from which the pipe was made, i.e., its plasticity. Microcomputer-controlled benders can be used to process pipes made of various materials. In practice, we deal with steel elements, including stainless steel, aluminium, brass, and copper.

The bending process on mandrel bending machine

Mandrel bending is the ideal method for bending pipes that have a small radius which is a very good solution that allows you to avoid any deformations or breaks in the pipe walls. The mandrel-bent pipe remains the same diameter at the bend point thanks to a special tool that is inserted into the pipe from the inside to stiffen it. The pipes are stiffened by a special flexible mandrel. This tool prevents any wrinkles from forming.

This process allows for the perfect radius with minimal distortion. As the shank cutting process requires specialist knowledge and experience, only our best specialists deal with it. What’s more, we use special equipment and specialised machines for this.

Another method of bending is known as stretch bending, which was originally developed for the aviation industry but is now also used for architectural purposes. It provides very precise bending.