Anti-corrosion protection before powder coating

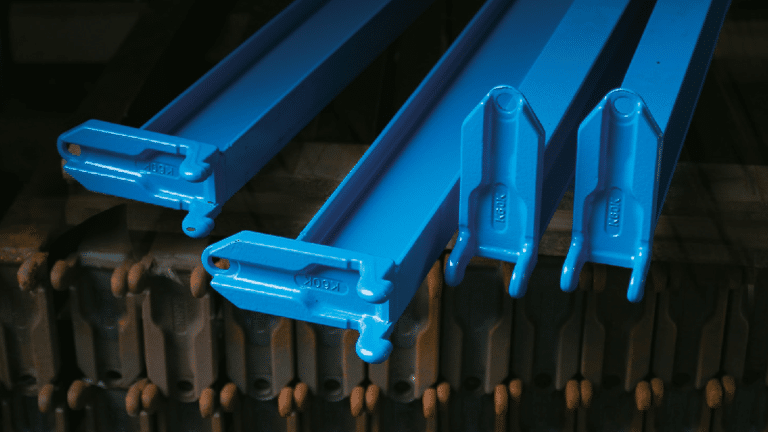

Products that are exposed to severe weather conditions often require double surface protection against corrosion. Elements that are to be served for many years must be properly prepared. One of the reliable methods that protect against corrosion is powder coating. Steel structures, fences, or metal gates are exposed to constant corrosive factors. Powder coating with previously performed anti-corrosion protection guarantees protection against rust, thanks to which the elements remain efficient and aesthetic for longer. Powder coating is a complicated process that requires proper preparation of the painted surface. Before powder coating, it is worth protecting the element by primer powder coating, electro-galvanizing, or hot-dip galvanizing. These processes significantly increase the material’s resistance to oxidation and also make the paint adhesion in the powder coating process better.

Powder coating without prior anti-corrosion protection

Powder coating in itself is a great way to prevent the corrosion of materials. Pigments contained in the paints are used effectively to prevent the formation of rust. In addition, the layers of varnish applied to the material in the process of powder coating have an insulating function and block the access of oxygen and water to the material. Therefore, it is possible to carry out powder coating without prior anti-corrosion protection. However, this method is only applicable to the treatment of elements used in rooms. Equipment located outdoors and exposed to changing weather conditions every day should be subjected to additional processes. As a result, their durability is significantly extended.

BASE POWDER PAINTING

Two-layer powder coating is an ideal method of protecting metal surfaces for many years. It works well both for powder coating elements used outdoors and indoors. In the process of powder coating with an earlier primer layer, zinc-free primer paints are increasingly used. Primer powder coating most often uses epoxy primers characterised by excellent adhesion and a great barrier effect, as well as polyester topcoats, which show high resistance to changing weather conditions. The use of these materials in the process of powder coating guarantees long-term corrosion protection.

Galvanizing and hot-dip galvanising

One of the most popular methods of protecting products against rust is galvanizing, followed by the service of powder coating. Coating the materials with a thin zinc coating makes them fully protected against the destructive effects of weather conditions such as water, sun, or air. There are two methods of galvanizing:

Fire and galvanic. The first is recommended, especially before powder coating elements are used inside. The second, on the other hand, is ideal for surfaces directly exposed to changing weather conditions when placed outside. Galvanizing is performed using electricity, that is, in the process of electrolysis. Ideally, it prepares the surface for further processing by powder coating. Plating makes the zinc coating smooth and uniform without any deformation. It does not change the weight or size of the products so that both the appearance and material properties remain the same.

The second method is hot-dip galvanizing. It consists of immersing the treated surface in water until it is brought to the state of liquid zinc. The coating produced in this way is much thicker and therefore also more durable. This process provides excellent corrosion protection; it does not even require further treatment and varnishing. Of course, powder coating can be done at the customer’s request, which will provide an additional protective layer and give the final appearance.