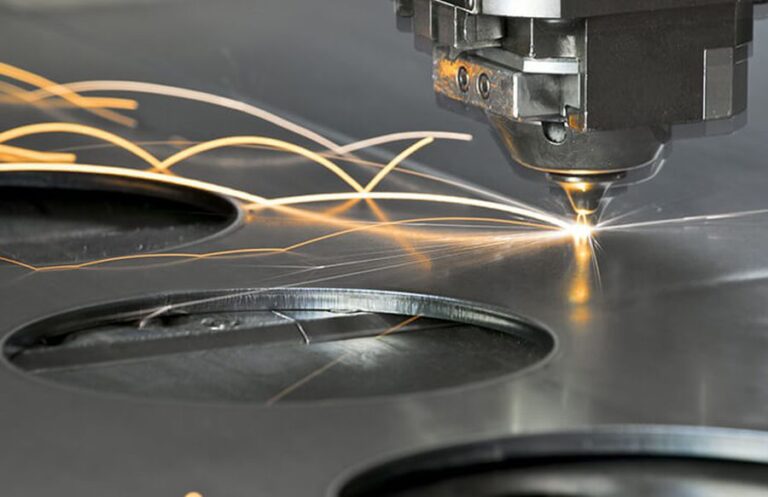

Laser cutting is one of the most innovative methods of metal processing. It has similar dimensional parameters to traditional machining, but it is distinguished by much more precise cutting, which reduces the need for secondary processing, reduces pollution, and emits negligible health-hazardous solvent gases. The fundamental difference between traditional cutting and laser cutting is the cutting factor, which in laser cutting is a hot laser beam and high purity technical gas. For a long time, laser technology has been employed in sheet metal processing, and it is continually gaining popularity. Because of its unparalleled cutting precision, regardless of the kind of thickness of the metal material, repeatability of the cut elements, and the capacity to serially produce irregularly shaped parts, the laser is widely used in many fields of the metallurgical industry and beyond.

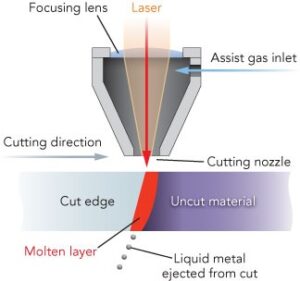

Cutting gases, also known as process gases, are essential for the proper execution of sophisticated services like laser cutting metal sheets. The employment of three fundamental cutting gases is the most commonly used among professionals in laser cutting techniques. Nitrogen, oxygen, and air are the three elements. The best and most consistent quality of the above-mentioned gases is required to accomplish the intended effects. The cutting gas or gas mixture is delivered via a nozzle system that protects the cutting region from the harmful effects of the surrounding air while simultaneously allowing the melted material to be evacuated. The three basic process gases of laser cutting are described briefly here.

Laser cutting with nitrogen

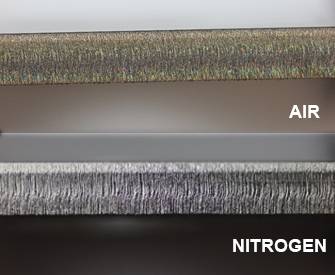

When working with galvanised steel, stainless steel, or aluminium, nitrogen laser cutting is most commonly employed. The laser beam melts and cuts the material during the cutting process, and the gas is required for cleaning, often known as “blowing out the melted material.” The enhanced power and pressure are what set this process apart from other laser cutting processes with oxygen.

When treating thin sheets where there is a risk of beam reflection, nitrogen is frequently advised. It aids in maintaining the cutting components’ flawless accuracy and repeatability. When employing nitrogen, the breadth of the material removed is usually less than 0.5 mm, which has a good impact on the amount of material lost and the efficiency of sheet disposal. We usually use nitrogen to cut sheets with a maximum thickness of 3 mm. Due to the amount of nitrogen needed, laser cutting thicker sheets is not profitable.

Another advantage of this solution is that it does not cause scale effects, i.e., gas corrosion. By using nitrogen for the laser cutting process when cutting black steel, you no longer have to worry about removing it, which lowers your rework costs. Nitrogen is widely used, especially in cutting cold-rolled sheet metal.

Among others, the following materials are cut with nitrogen:

- Black steel,

- Galvanized steel,

- Stainless steel,

- Aluminum

Laser cutting with air

Air cutting is by far the cheapest laser cutting option. To use this method, the laser must be equipped with a source of compressed air, such as a compressor. Due to the high pressure of the air stream, the liquid material is removed from the cutting gap. Due to the fact that this method does not burn the material, the cut surface is free of oxides. However, due to the poor quality of edge processing, when using this type of cutting gas for laser cutting, we have to take into account that it will be necessary to spend more time, and money, on reworking the elements.

Laser cutting with oxygen

Laser cutting with the use of oxygen is ideal for cutting sheets of greater thickness. The gas in the laser cutting process not only protects the lens against fumes and spatter but also cools the edges of the cuts and cleans them of melted metal filings and oxides. Oxygen also has the properties to accelerate laser cutting, entering into chemical reactions with the cut material. When laser cutting with oxygen, the additional heat resulting from the oxidation of the metal allows for high cutting speeds or cutting thicker materials.

The result of cutting with oxygen is the formation of scale, which must then be removed by grinding, sandblasting, or shot blasting, especially if the surface is to be varnished. Regarding black steel, in the Elektron company, we most often cut hot-rolled sheets with oxygen due to the natural scale produced in the process of their production.