We are all used to thinking that only the least technologically advanced solutions can cost pennies. Especially when it comes to services as specialised and complex as laser cutting. Well, things are completely different these days. It is the most innovative method and requires specialised equipment that reduces the cost of implementation. Why is this happening? We’ll find out soon.

Why is laser cutting a cheaper solution than traditional machining methods?

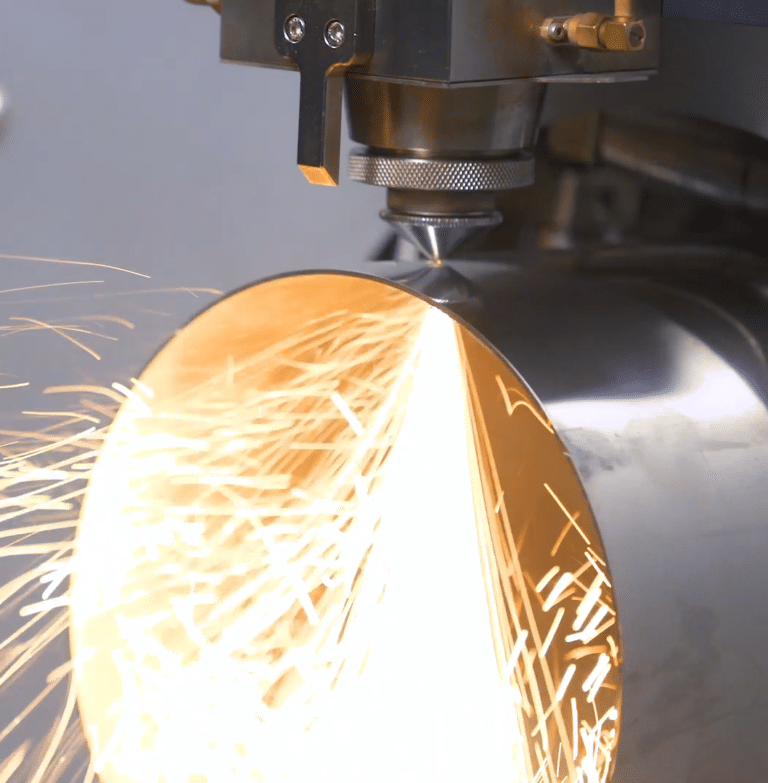

Laser cutting reduces order fulfilment costs, especially for large-size, mass orders or those requiring high accuracy and precision. What factors contribute to the low cost of laser cutting?

- Automation of the laser cutting process

- Precision laser cutting

- It is not necessary to process the cut elements.

What is the cost and possibilities of laser cutting compared to other cutting methods?

You are probably wondering what the cost of laser cutting is compared to other methods. We can say with certainty that this is the best method, both in terms of quality and versatility of use and low price. Taking into account oxygen cutting, it must be admitted that its cost is relatively low, but at the same time, its implementation is slow. On the other hand, plasma cutting is more expensive and is inferior to laser cutting in terms of accuracy, and its product requires subsequent processing. Cutting with a water jet seems to be an attractive method in terms of accuracy, but it is extremely time-consuming to implement and extremely expensive. So, from this comparison, it is clear that if you care about an attractive price and good quality, only laser cutting will meet your expectations.