Which sheet metal cutting method to choose?

Metal sheets are very versatile and can be used for many things in architecture and decoration, like walls, roofs, ceilings, and sculptures. It is a popular material because of its versatility and the ability to bend easily and take all kinds of shapes and forms. There are many different types of metal sheets made of different materials, with different thicknesses and levels of cutting strength. Sheet metal is a metallurgical product, the thickness of which is much smaller than the length and width, and they usually range from tenths of a millimeter to several dozen millimeters. Knowing the specific details of a product helps us choose the best cutting method. If you are bothered by the title question and want to know the best methods of cutting metal sheets, keep reading. In a moment, we will describe everything in detail. Below you will find descriptions of the different cutting methods with their most important advantages, disadvantages, and differences.

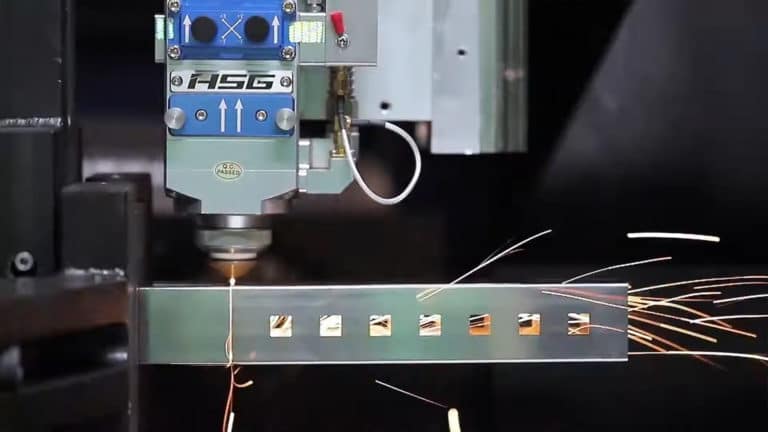

Laser cutting

Laser cutting is one of the most modern processing methods, with similar dimensional parameters as classical machining but with significant time savings and increased precision. The main difference between the above-mentioned methods and laser cutting lies in the cutting factor used, which in this case is a hot laser beam and a high-purity technical gas. The use of these elements makes it not only ergonomic but also ecological in comparison to the previous ones. Sheet metal laser cutting is the best choice for people who care about the perfect implementation of many identical elements in a short time. Big businesses can use this new technology for efficient manufacturing because it allows for high repeatability and minimal waste and can cut regular and irregular shapes quickly.

Plasma cutting

Plasma cutting is a process used to cut various types of metals, e.g., steel, aluminum alloys, copper alloys, etc., where a plasma arc is used. Plasma cutting can be carried out in a mechanized manner, using numerically controlled machines, or by hand, where hand torches are mainly used. Mechanized cutting processes mainly concern cutting with the use of CNC cutters or industrial robots. The source of heat, i.e., the element that melts and thus cuts the metal, is the plasma arc glowing between the electrode and the workpiece. Plasma cutting is an advanced and effective machining method that is characterized by precision, but in this respect, it gives way to the laser cutting method, which is much more accurate, allows you to cut irregular shapes, and leaves smooth edges, which reduces the time needed for grinding.

Water jet cutting

Cutting with a jet of water, abrasive machining, otherwise known as the Waterjet method, is the general name for the technology of cutting or cleaning various materials using high-pressure water. This is a method that works very well when cutting sheets of a small thickness but has problems puncturing harder and thicker materials. It is as precise as plasma cutting but takes much longer compared to laser cutting, making it not well suited for mass production. An additional advantage of this technological solution is the fact that the final product does not require secondary edge processing.

Each of the above-mentioned methods of cutting metal sheets has its advantages and disadvantages. However, after careful consideration and a closer look at the cutting parameters, our recommendation is to choose laser cutting. This is by far the best ratio of time, financial contribution, precision, and accuracy.