If you are urgently looking for a company that specialises in laser cutting, be sure to test the services we offer. We are a company based in Poland and work with many companies in Bristol. By choosing our laser cutting services, you will gain extensive knowledge of our qualified employees who, thanks to engaging in training and numerous projects, can operate the most advanced machines. Our specialists will undertake any task, even the most difficult one, to satisfy our customers’ expectations. What’s more, regardless of whether an individual client or a company comes to us, we provide everyone with an immediate quote, attractive terms and conditions of cooperation, and quick completion of the task entrusted to us.

It is worth mentioning that we also have an extremely modern machine park, extensive facilities, and many different materials that are raw materials recognised around the world. The equipment our employees use is a TRUMATIC laser, as well as a cutter in the L 3050 variant with a power of 5 KW. Therefore, they are the highest quality equipment, characterised by excellent quality and accuracy in cutting sheets to a maximum thickness of 25 mm.

Bristol is a great location for you to decide to use the laser cutting services we offer. We provide this extremely innovative technology that allows us to process non-metallic materials as well. However, the finish of the product will not be needed as the quality of the cut edge will remain high. This will save you time and resources. Moreover, this process ensures repeatability of details and cut elements and, what’s very important, prevents material losses.

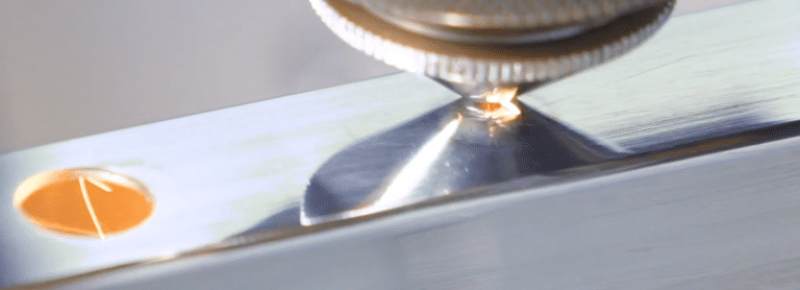

Even though laser cutting is a thermal treatment, it does not cause any deformation of the material. This process takes place remotely, for the sake of safety, as a strong beam of light is concentrated on the surface of only a few millimetres. The software of our machines also allows you to make corrections at any time during production if there are any sudden changes in the design. It can cut simple as well as complex forms. As a company, we also ensure timeliness and quick completion of work, followed by quick delivery to your place.

ELEKTRON would like to introduce our offer a bit closer to you and, in particular, to tell you about our major service, i.e., professional laser cutting of metal pipes and profiles. In the course of our activity, we faced many different tasks and challenges, and based on many years of experience, we have now mastered all aspects of laser cutting and metal processing. We are at the forefront of the 3D cutting market mainly due to two equally important factors.

First, and most importantly, is our trusted and qualified team. We assume that it is worth investing in employees, which is why each of our specialists has extensive theoretical and practical knowledge, gained not only during the implementation of new orders but also thanks to numerous courses and continuous training conducted at the premises of our company. For this reason, you can trust our team that they will not only do their job but also propose the best option related to the implementation of a specific project.

The second is our care for the use of the highest quality materials and tools. We have a machine park rich in the latest devices, the resources of which are constantly supplemented with the highest class processing devices. For laser cutting of pipes and metal profiles, we use the innovative, which is one of the most reliable machines in its class. Taking advantage of its capabilities, we perform perfect 3D laser cutting of materials such as brass, copper, black and stainless steel, aluminium and others. The maximum cutting thickness of these materials is 8 mm for carbon steel, 5 mm for stainless steel, 3 mm for brass, aluminium, and 2 mm for copper.

We offer two different types of services related to laser cutting of profiles: laser cutting of square profiles 20 × 20 and 150 × 150 with a length of up to 6500 mm; and 3D laser cutting of other tubes with a diameter not exceeding 210 mm (e.g. 150 × 20 mm). Our professional equipment has the option of automatic loading (3600-6500 mm long) and material unloading (3000 mm), while the maximum thickness of the cut varies depending on the material. In the case of black steel, it is 8 mm, stainless steel 5 mm, brass and aluminium 3 mm, while the thickness of the copper element cannot exceed 2 mm.

We manufacture steel components, delivering projects from the client’s concept to the finished product.