In our offer, you will find a robotic welding service with the fastest and most modern welding robot from PANASONIC.. Nowadays, technology allows the use of machines that successively improve production while increasing the quality of services. The PANASONIC welding robot is a reliable machine used for the serial production of metal parts. The welds made by the robot are durable and aesthetic at the same time. The use of a welding robot ensures remarkable weld accuracy. The use of a welding robot not only significantly speeds up the serial production process but also guarantees durable welds for years. Welding robots are also perfect for the production of metal elements for furniture. The quality of the weld made by the welding robot stands out significantly compared to the weld made by hand, as it eliminates any unevenness and prevents the formation of craters. One of the many advantages of the welding robot is its ability to determine the thickness of the weld depending on the production of the product for which we programme this modern machine. As we mentioned before, welding robots are used to produce metal elements of furniture, ensuring 100% repeatability of the work performed and the aesthetics of the weld, which in this case is set as low as possible as the furniture will not be subjected to unusual “effort.” In the production process of metal elements intended to serve as frames, heavy reinforcement, balustrades, or metal cellars, the thickness of the joint is raised, appropriately adjusting the product for future use.

Robot model PANASONIC | TM-2000 | ||

Number of axles | 6 | ||

Movement range |

Arm | Rotation | ±170° |

Upper arm | -90° do 165° | ||

Front arm | -80° do 210° | ||

Joint | Rotation | ±270° | |

Flexion | -160° do 95° | ||

Twist | ±400° | ||

Maximum angular speed |

Arm | Rotation | 195°/s |

Upper arm | 197°/s | ||

Front arm | 205°/s | ||

Joint | Rotation | 425°/s | |

Flexion | 425°/s | ||

Twist | 629°/s | ||

Max. weight limit | 6 kg | ||

Repeatability | ±0,10 mm lub | ||

Brakes | Wszystkie osie z | ||

Mass | 217 kg | ||

Radius | 2011 mm | ||

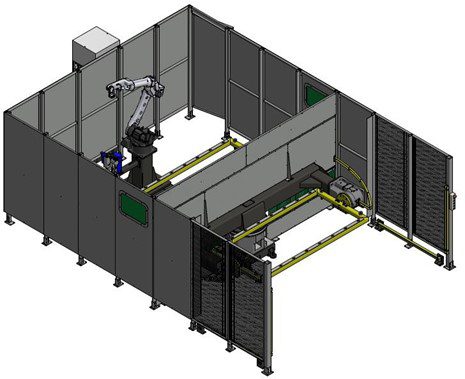

What does a welding robot consist of?

The welding robot consists of two main components. One of them is the robot itself, which consists of an arm at the end of which is a torch with active wire feeding. The Servo Pull welding torch repeats the wire advancement and retraction movements with a high frequency, ensuring a constant short cycle of the welding arc, which reduces the amount of spatter by more than 80%. The second main element is the rotary table, which allows for increased work efficiency. The table is divided into two identical parts, acting as an exchange of robot workstations. When the robot welds the stacked elements on one half, the worker has the opportunity to prepare another set of metal elements for welding. This allows for continuous production without the need to stop the machine unnecessarily.

In addition, the device is equipped with a touch sensor; a gas nozzle or welding wire has the function of locating the welded joint by touching the welded material before the welding process. When a deviation is detected, the welding line is automatically corrected in the program. In addition, the feature that distinguishes our robot from others is the integration of the robot controller with the power source. The controller allows full control over the welding process, which results in the achievement of very high-quality welds.

The PANASONIC TAWERS robot can be welded using the following methods:

– SP-MAG

– PULSE MAG

– MIG

– TIG DC