Sheet metal is by far one of the most popular raw materials used in various industries; manufacturing, construction, metallurgy, and many other sectors. To achieve the desired size, thickness, and shape of an element made of this material, it is necessary to apply a plastic coating. One of the most common techniques used to bend sheet metal is press brake bending. Sheet metal bending with press brakes is constantly gaining popularity, which is why we decided to introduce this technological method, the tools used in it, and the materials.

What is sheet bending?

The procedure of the sheet metal bending technology consists of exerting a force on the plane aimed at changing the shape, resulting in a permanent change in the curvature of the bent element without a significant change in the thickness of the sheet itself. By using this moulding technique, various shapes, including relatively complex shapes with a significant number of bends, can be obtained. However, bending as a group of plastic working processes for metals and alloys and other materials includes bending, straightening, and coiling sheets of various thicknesses. Sheet metal bending can be performed on presses using the following tools:

- stamping dies,

- press brakes,

- stencil,

- rollers

Sheet metal bending on a press brake

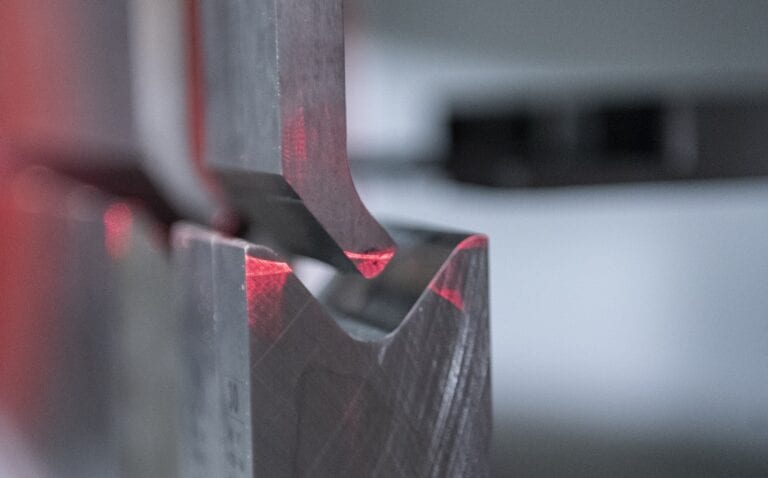

Sheet metal bending with press brakes is a process consisting of shaping flat sheet metal parts to the desired shape. Most often, sheet metal bending takes place in the processing process right after it is cut. Then, the workpiece is placed on a die with a V-shaped opening. Using the appropriate bending functions, the sheet is passed through the above-mentioned workpiece, as a result of which its shape changes. Press brakes are perfect for bending stainless and steel sheets and bending aluminium sheets.

What is a press brake?

A press brake is a tool for processing metal, colloquially called a folding machine or a folding machine. The press brake is most often used in the process of plastic working of sheets made of various materials. The use of appropriate punches and dies allows sheet metal to be bent at any angle as well as crimped or corrugated on its surface.

Most often, a press brake is made of a C-shaped body with a lower beam, sometimes movable, set in the horizontal plane, to which a die is attached, and an upper beam movable in a vertical plane with a punch embedded in it, moved by two synchronised hydraulic cylinders. The most important parameters characterised by press brakes are pressure force expressed in tonnes and maximum bending length expressed in millimetres.

Types of press brakes used for sheet bending

- hydraulic,

- electric,

- mechanical

Press brake hydraulic

Such a sheet bending press, the specificity of which lies in the use of a system in which the oil, as a result of the action of a hydraulic pump, changes its physical properties and is brought to a state of high pressure, allows for a very high pressing force. Hydraulic presses are characterised by the greatest pressing force of several dozen or several hundred tonnes and are most often used for bending thick and long sheets, the length of which exceeds a few meters. Hydraulic presses are used, among others, when it comes to bending steel and aluminium sheets.

A mechanical press brake

The operation of a mechanical press brake is based on the operation of an electric motor to rotate the flywheel. The momentum of the wheel transferred to the beam causes it to move. The clutch engages the flywheel to drive the crank mechanism, which moves the arm vertically, thereby bending the sheet into the desired shape. The greatest advantages of mechanical press brakes are accuracy and precision, and this type of tooling is particularly effective when it comes to bending aluminium sheets.

An electric press brake

Edge benders of this type are based on two servo motors operating on the Y1 and Y2 axes, which enables the sheet bending process to be carried out. This type of bending machine is characterised by very high precision and speed. Pneumatic and electric presses do not have such a high pressing force, but very often they are much faster than hydraulic presses and are used for serial bending of small sheet metal parts.

What material bending are press brakes best suited for?

Press brakes are used primarily when it comes to:

- bending of steel sheets

- bending stainless steel sheets.

- bending aluminium sheets.