Metal cutting is one of the most basic and thus most popular issues when it comes to the processing and production of metal structures, car parts, sheet metal, hydraulics, building elements, or furniture. It is thanks to the universal use of metal in an industry that the methods of its processing have also developed so much—we have such a number of variants that not only laypeople feel lost but also people familiar with the industry. Therefore, today we will try to find out which of the cutting methods is most advantageous in the production of complex shapes.

Which metal cutting method is optimal for the mass production of complex shapes?

Unfortunately, the answer to this question is not clear-cut because it all depends on the specifics of the material and design, what equipment and resources we have, and the type of cut we want to obtain. One method is suitable for thicker sheets, while the other method is perfect for cutting thinner elements. There are cheaper and more expensive methods; the precise ones are suitable only for the production of simple patterns. Therefore, to consider this issue as well as possible, we decided to take a closer look at the two most popular methods of cutting, i.e., water and laser, and consider the advantages and disadvantages of each of them, to choose the most appropriate process for a specific application based on this data.

Water or laser cutting?

1) Water cutting

The water cutting technique, also known as hydro abrasive or waterjet, is based on the erosion of the material by a jet of water under high pressure.

- The advantages of water cutting

The most significant benefits of waterjet technology are its versatility and dependability, as the water jet can cut almost any type of material with a thickness of up to 300 mm. Compared to the possibilities of other cutting technologies, this is quite an achievement. In addition, the water cutting technique is much more economical in terms of time because the cut edges are not subjected to high temperatures and remain smooth, and the finished element does not require additional processing. The use of the cutting technique can also be considered ecological, as no harmful gases are produced in this process.

- Water cutting disadvantages

The cost of waterjet cutting machines is usually much higher compared to plasma cutting machines due to the high price of the multiplier pump, and in addition, the cost of the jet cutting hour is high due to the price of navy blue abrasive sand used for cutting. Another disadvantage of this method is water. It can only be used for the treatment of flat surfaces and with a constant thickness

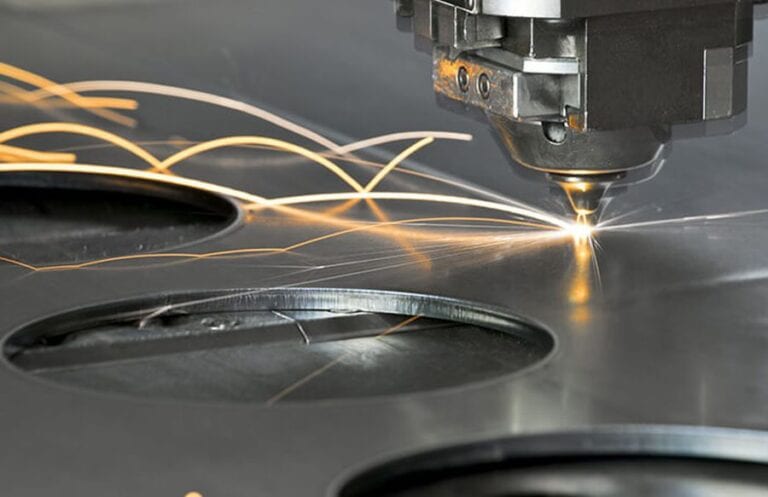

2) Laser cutting

Laser cutting is the most modern of the cutting options, using a laser beam in combination with technical gases—you can learn more about it by clicking here.

- The advantages of laser cutting

Processing with a laser is associated with the possibility of avoiding damage and deformation of adjacent elements because, in laser cutting, the radiation is selectively focused only on the cutting area, which guarantees extraordinary precision. It is because of this ideal precision and repeatability that laser cutting is currently used in almost all industries. This technique allows each component of the project to be accurately reproduced. The speed of implementation additionally characterises laser cutting. This is due to the low error rate combined with no need for secondary processing as the laser-cut edges are perfectly smooth.

- Laser cutting disadvantages

Even though it is one of the leading cutting methods, in this case, it is not without its drawbacks. The first, and perhaps most importantly, is the high cost of the laser cutting device. Not everyone can afford it because it is such unique and cutting-edge technology, and there aren’t many businesses with people that are experts in this area.