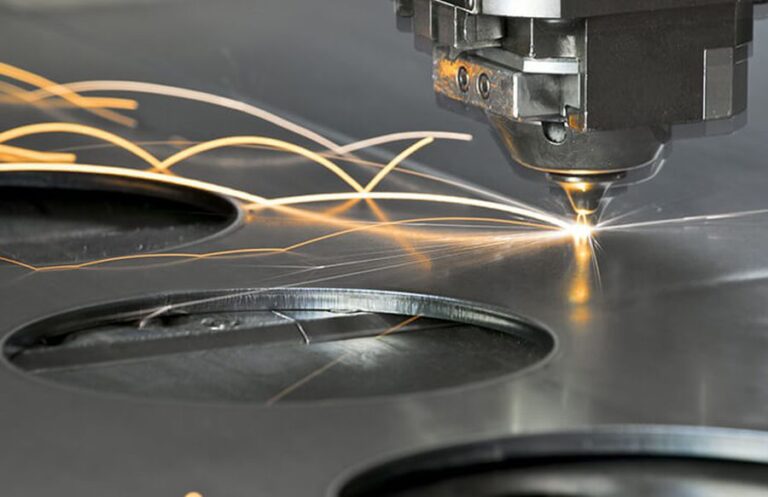

Nowadays, laser cutting is the most modern method of cutting elements in various materials. It will be perfect for cutting aluminum, steel, copper, brass, ceramics, glass, or wood. Thanks to its precision and accuracy, laser cutting is used in many industries: construction, aviation, architecture, the furniture industry, and everyday objects. Many people replace traditional cutting methods with lasers. Cutting complicated shapes has become much simpler and cheaper since the first use of lasers.

How does the laser work?

The laser beam hits the surface of the material at an extremely high temperature, which causes it to melt or completely vaporize. Reactive cutting is a very effective process that involves using a stream of oxygen or a mixture of oxygen and argon. Another method of laser cutting is cutting with the use of cracks. This process consists of creating gaps in the material and works great for materials with a thickness of no more than 1 mm. For cutting high-alloy metals such as aluminum, titanium, and magnesium, use the liquid.

Laser cutting - precision

Laser cutting is a modern and precise method that uses advanced technology to cut different types of materials. This method allows the user to obtain a perfect cut. It is characterized by the possibility of almost 100 percent repeatability of the cut elements. At the end of the process, the element is ready for use, and no additional processing is required. Thanks to these advantages, laser cutting has become a fast and cheap method. Cutting complicated details in any shape takes place with perfect accuracy and makes maximum use of the material through the optimal arrangement of the cut elements. The finished element, in terms of quality and visuals, will undoubtedly satisfy even the most demanding customers.

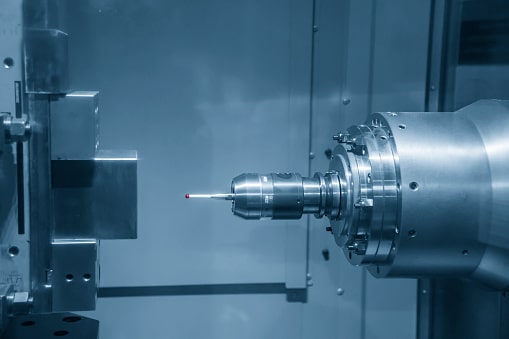

Laser cutting - application of 2D and 3D technology

2D laser cutting is designed for the processing of flat materials of various thicknesses; it allows for cutting complicated shapes and is characterized by great effectiveness and efficiency. The technology of fully automated 2D laser cutting is a very fast and accurate process, allowing for maximum use of the material, which in turn translates into lower order costs. Customers who care about accuracy and repeatability most often choose the method of laser cutting.

3D laser cutting is a technique that can cut pipes and profiles, which are used in many industries. 3D technology gives the possibility of perfect cutting into various types of elements. Similar to 2D laser cutting, the result does not require additional processing, and the details are perfectly smooth. The 3D laser is also an ideal solution for cutting thin pipes, which are easy to bend when processed traditionally.

Thanks to the above-mentioned advantages of laser cutting, this technology is classified as the most modern, precise, and quick method of cutting, often irreplaceable if we want to make complicated elements and we want almost 100% repeatability of the cut. Innovative software guarantees a cutting accuracy of 0.1 mm. This is impossible to achieve with traditional methods.