LASER CUTTING – PROCESS REPEATABILITY

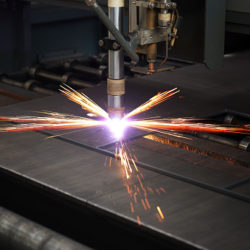

Laser cutting is currently the fastest and most modern method of metal cutting. Cutting out hard-to-reach places and profiles has become much easier since this method was first used. The focused light of the laser beam falling on the surface hits the cut element and heats its surface, which causes melting or evaporation. It is important[…]