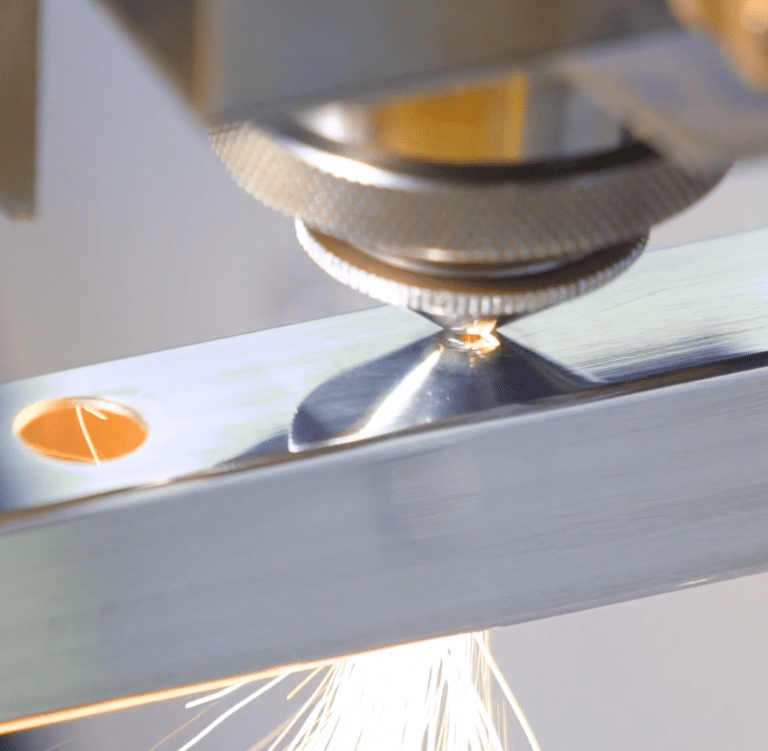

In today’s highly technologically advanced times, laser cutting of pipes and profiles is considered the fastest, most modern, and most accurate method of processing these types of elements. It provides the ability to accurately cut complex details, guarantees the production of high-quality elements, and complete repeatability of cutting subsequent parts, which results in a sharp decrease in the time needed to carry out mass production. Laser cutting of pipes and profiles guarantees quick cutting of complex shapes of various sizes in a short time without reducing the quality of the cut.

Characteristics of laser cutting of pipes and profiles

The modern technique of laser cutting is a guarantee for achieving a high speed of execution of orders while maintaining the perfect smoothness of the cut edge. Almost one hundred percent automation of laser cutting of pipes and profiles gives the possibility of obtaining shapes that allow the production of steel, aluminium, or brass elements that are complex in terms of shapes. Compared to other methods, the one that uses the laser is distinguished by optimal cutting efficiency, speed of implementation, and no need for secondary processing, which even more speaks for its use in the case of mass cutting of metal pipes and profiles. Laser cutting of pipes and profiles is a technique that is appreciated and still used in the industrial, automotive, construction, and other industries. Due to its universal application, laser cutting of pipes and profiles is currently one of the most basic forms of processing in the production sector.

Reducing the production time thanks to the use of laser cutting of pipes and profiles as a source of customer satisfaction

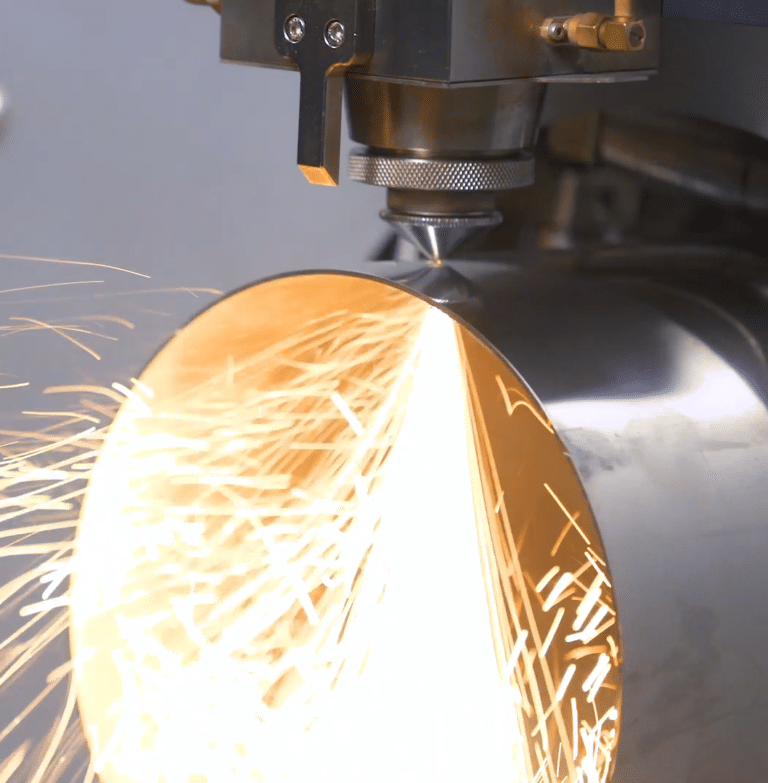

Due to the rapid development of the metalworking sector and the wide use of the most modern machines, cutting pipes and profiles is now a basic process in the production of many different items. Compared to traditional methods of mechanical processing, laser cutting of pipes and profiles makes it possible to produce bouquets of complex shapes in record time. Why? Well, only one device is used during this process, it is almost entirely automated, and the result does not require further processing. All these factors significantly reduce production time!

An innovative method of laser cutting pipes and profiles

The dynamic development of technology and the constantly growing demand for metal elements and their wide use in processes have contributed to the more frequent use of spatial processing, which is best implemented thanks to 3D laser cutting devices. Compared to conventional methods, 3D laser cutting provides much more precise material processing. Above all, laser cutting of pipes and profiles offers a guarantee of repeatability and speed of order execution. Specialized laser cutting machines allow you to work at a fixed angle and cut even the most complex shapes.

Among the most important advantages of laser cutting in production, one can distinguish the possibility of carrying out many operations at the same time, as well as the use of accurate measurements, which significantly affect the quality of cutting and improve the entire process. Thanks to the use of machines for laser cutting pipes and profiles, you can also expect a reduction in the cost of material purchase and the working time of specialists in the field of cutting.